Broaching Tool Regrind

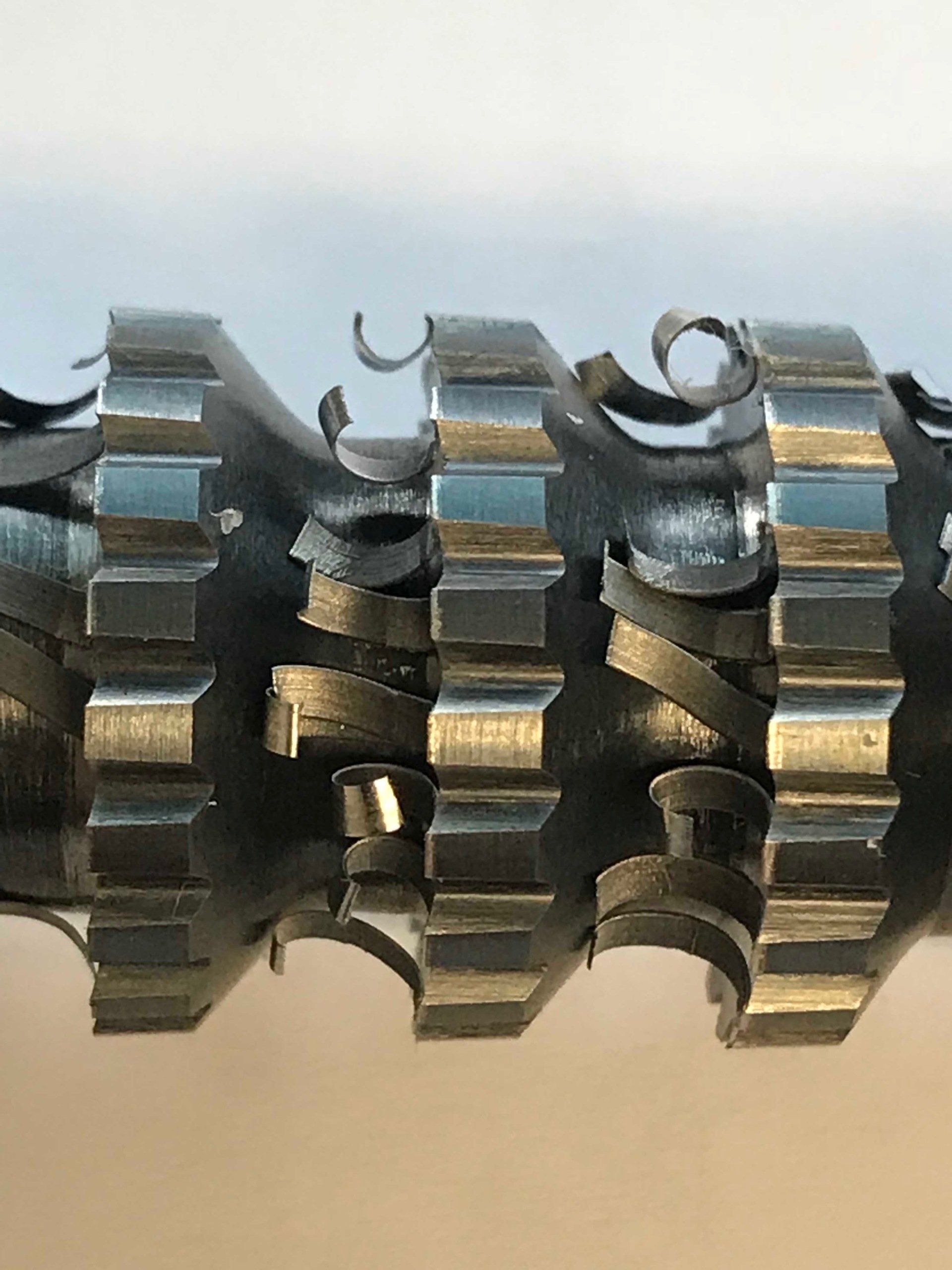

Don't let your tools wear like the one shown at the top of this page!

There are two critical factors for managing tool sharpening services. Firstly, understanding when you need to change out your broach, and secondly, having the tool evaluated and then serviced accordingly by professionals, preferably a manufacturer. Getting these right will help facilitate achieving maximum tool life and therefore minimum overall cost per part.

IMPORTANT! When sending your tools for service please provide your supplier with all the information you have regarding the reason(s) you have sent the tool in. Our orders are mostly described as "regrind", when far more than that may be required - Tools may be cutting small or big, tearing in localised areas but otherwise good, cutting with excessive run-out, producing unusual noise or unexpected heat, producing different swarf patterns or swarf behaviour to normal. If the supplier being used is not the original manufacturer then some component and workpiece data is always useful. We always attempt to fully evaluate tools received for "regrind" - tooth geometry, cutting edge condition (top and faces), cutting edge damage, cutting geometry in particular face (front rake) angle, condition of pull end features etc.

Spline broach showing top wear, face wear, and swarf retention

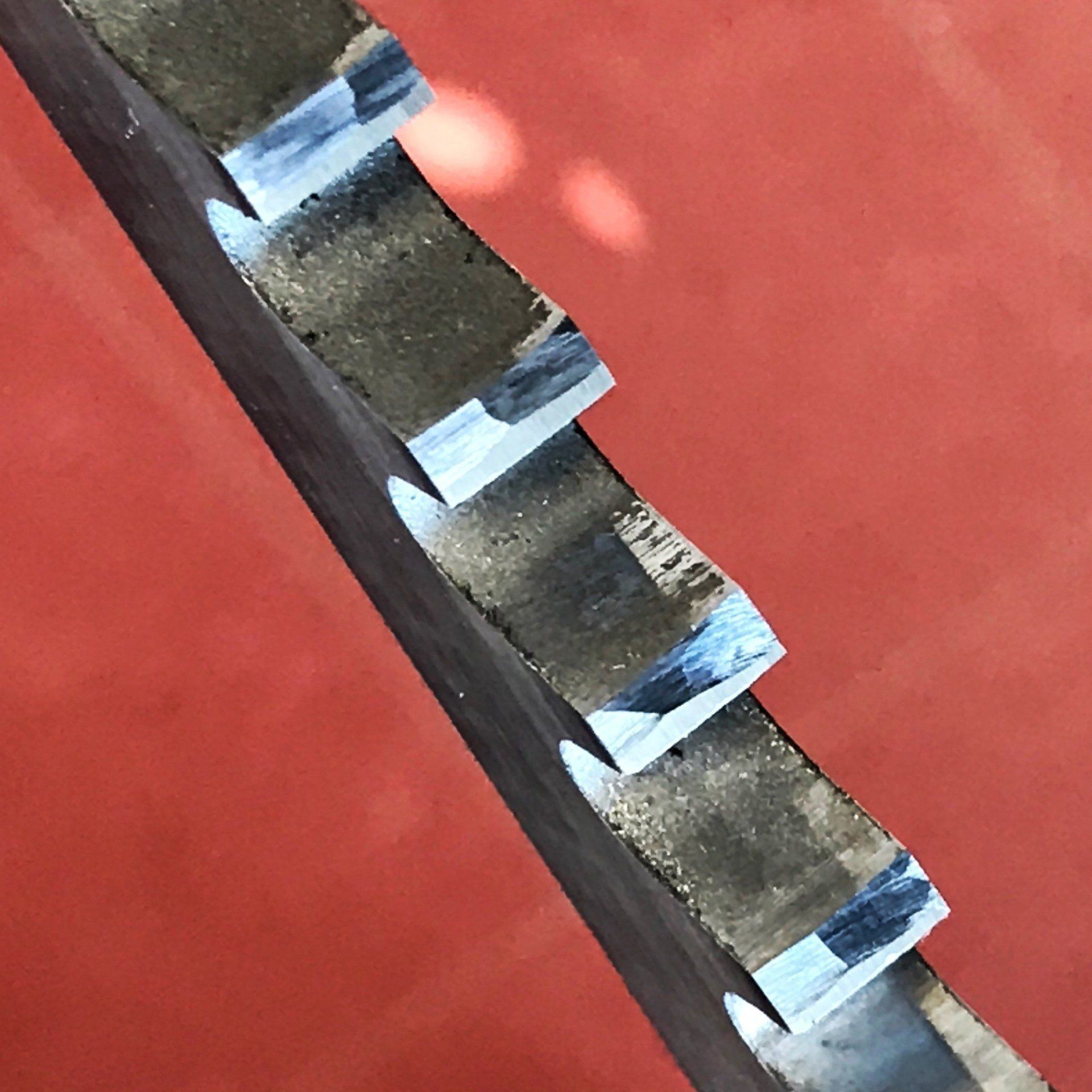

Involute broach with damage - rather than wear - on cutting edge. Handle broaches with care.

Excessive wear and poor grinding - don't let your broaches end up like this, send them to a professional such as Alcester Broach