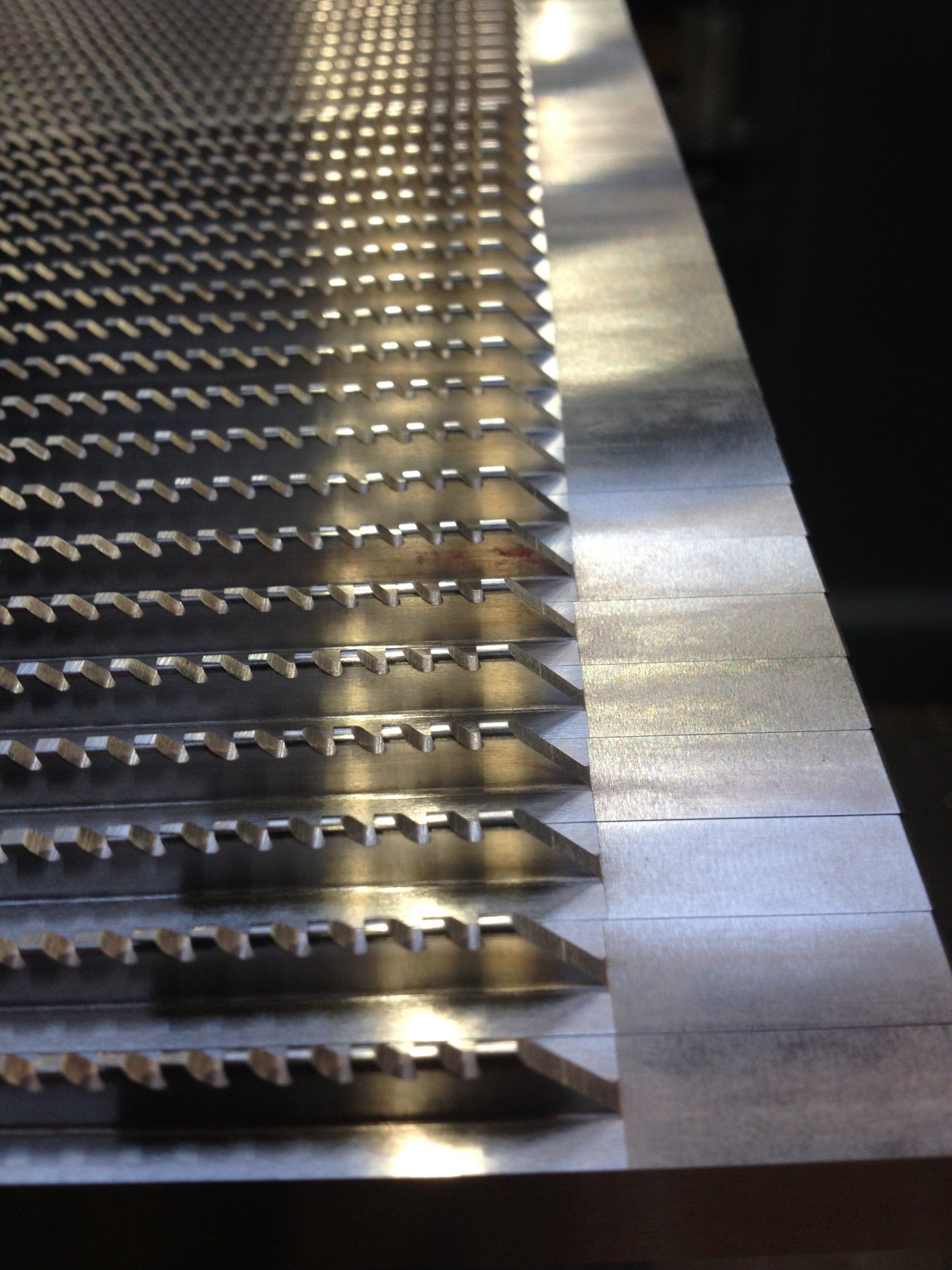

Surface Broaching Tools

SURFACE BROACHING TOOLS:

like all broaches are capable of complex machining at impressive production rates. Yes the set-up of a surface broaching application tends to be more complicated with high levels of fixturing required than standard internal broaching, but the results are nevertheless compelling when costed against other machining methods such as milling or EDM etc.

TOOL MATERIALS:

We offer you tools made in conventional and powder metallurgy High Speed Steels. Including standard and premium grades M2, M35, M42, ASP2023, ASP2030

and equivalents (HS6-5-2, HS6-5-3, HS-6-5-2-5, HS 2-9-1-8, HS6-5-3-8) but only purchased from the worlds leading HSS manufacturers.

TOOL COATINGS:

Coating of broaches is not without its technical difficulties, but when it is right it can work very well. We have suppliers able to offer you TiN, TiCN, TiAlN, AlCrN, and combinations.

TYPES & APPLICATIONS:

Ratchet Forms - Hand Brake, Handcuff etc

Connecting Rods

Spanners - Open ended types

Automotive - Head Rest notches etc

Aerospace - Turbine Disc Broach Tools ("Fir-Tree" Broached Forms)

Steering Racks

CHARPY NOTCH BROACHES

We offer a range of broach tools for producing notches in impact test specimens, most commonly for the CHARPY and IZOD tests, to all recognised standards. We have a wide range of standard and premium material tools in coated and plain options, all common options are FROM STOCK.